Copper Foil Tape is a special tape consisting of a copper foil substrate and a pressure-sensitive adhesive layer. It has excellent electrical conductivity and shielding effect, and is widely used in electronic, electrical and communication equipment for shielding electromagnetic interference, grounding and conduction. Copper Foil Tape also has excellent corrosion resistance and mechanical properties, and plays an important role in the field of electromagnetic compatibility (EMC).

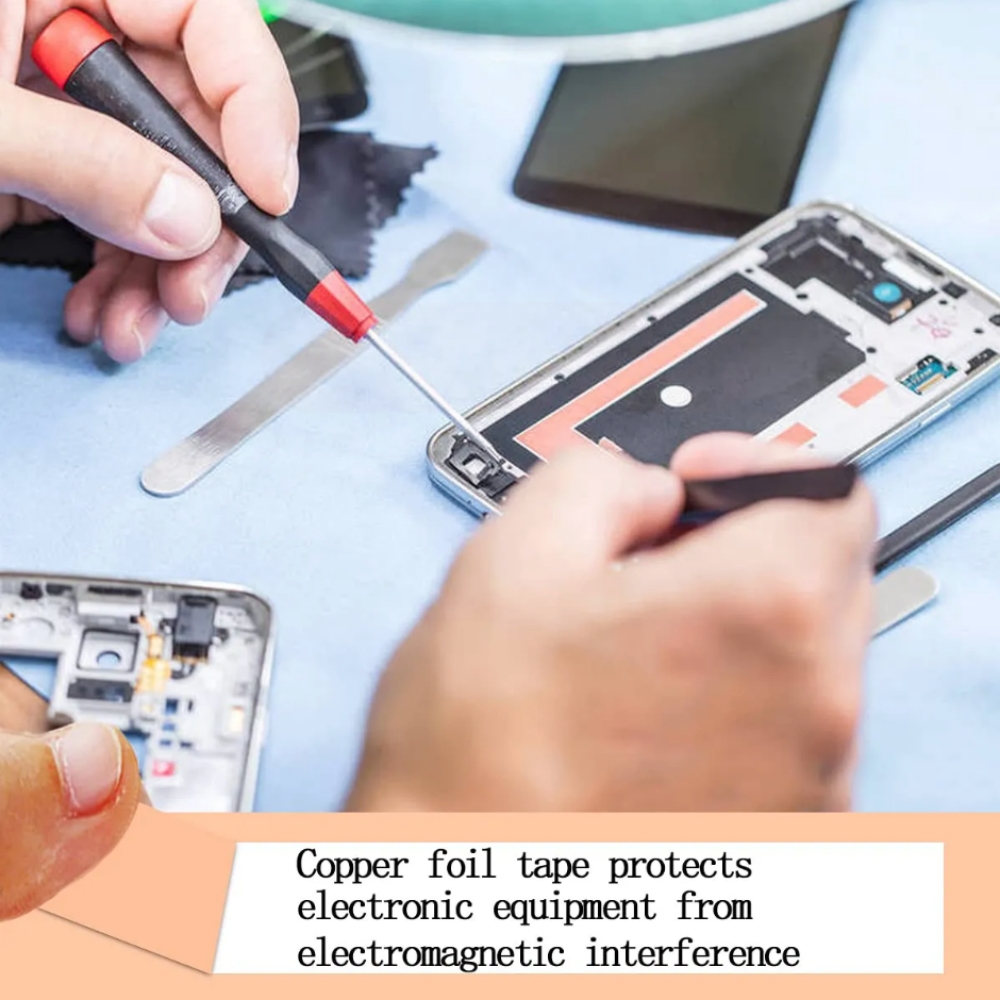

– Excellent electrical conductivity: Copper foil tape is known for its high conductivity, which can provide a good electrical connection between the entire surface of the tape and the adhesive layer. This makes it widely used in electrical, electronic and communication equipment to shield electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring the stability of signal transmission and the normal operation of equipment.

– Excellent shielding effect: The metal substrate of copper foil tape can effectively shield electromagnetic waves and radio frequency interference, protecting electronic components from external interference. This shielding effect is particularly important in equipment that requires high-precision signal transmission, such as computers, mobile phones, communication equipment, etc., to ensure the performance and stability of the equipment.

– Good corrosion resistance: Copper foil tape has excellent corrosion resistance and can maintain its performance and structural stability in various environments. It can resist corrosion from the atmosphere, moisture and various chemicals, ensuring reliability and durability in long-term use. It is often used in aerospace, marine and industrial environments.

– Strong mechanical properties: Copper foil tape has excellent mechanical strength and is tear-resistant and wear-resistant. It can maintain integrity and stability under mechanical stress and physical impact, and is widely used in occasions requiring high strength and durability, such as wrapping and fixing of motor coils.

| ① Excellent conductivity The tape is highly conductive and can provide a good electrical connection between the tape surface and the adhesive layer. This makes it widely used in electronic, electrical and communication equipment to shield electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring the stability of signal transmission and the normal operation of the equipment. |

| ② Excellent shielding effect The metal substrate of copper foil tape can effectively shield electromagnetic waves and radio frequency interference, protecting electronic components from external interference. This shielding effect is particularly important in equipment that requires high-precision signal transmission, such as computers, mobile phones, communication equipment, etc., to ensure the performance and stability of the equipment. |  |

| ③ Good corrosion resistance The tape has excellent corrosion resistance and can maintain its performance and structural stability in various environments. It can resist corrosion from the atmosphere, moisture and a variety of chemicals, ensuring reliability and durability in long-term use, and is often used in aerospace, marine and industrial environments. |

④ Strong mechanical properties The tape has excellent mechanical strength and is tear-resistant and wear-resistant. It can maintain integrity and stability under mechanical stress and physical impact, and is widely used in occasions requiring high strength and durability, such as wrapping and fixing of motor coils. |  |

| Brand | JASTOM | Breathability | Airtight |

| Product Name | Copper foil tape | Transparency | opaque |

| Material | Copper foil substrate and pressure-sensitive adhesive layer | Writability | Generally not writable |

| Color | Copper color (copper foil color) | Environmental Protection | / |

| Size | 50M*50Mm*0.12Mm (Can Be Customized At Will) | Packing | Single roll packaging Or packaged according to customer requirements |

| Adhesive Type | Pressure sensitive adhesive (commonly acrylic adhesive or conductive adhesive) | Use | Manual operation is convenient and fast |

| Viscosity | High viscosity to ensure a secure bond | Applicable Scene | Electrical appliances, automobiles, construction, packaging, electronic equipment, etc. |

| Temperature Resistance | -20°C to 150°C | Producing Country | China |

| Water Resistance | Excellent | Certificate Authentication | SGS |

| Tear Resistance | high | Label Customization | Logo Can Be Customized At Will |