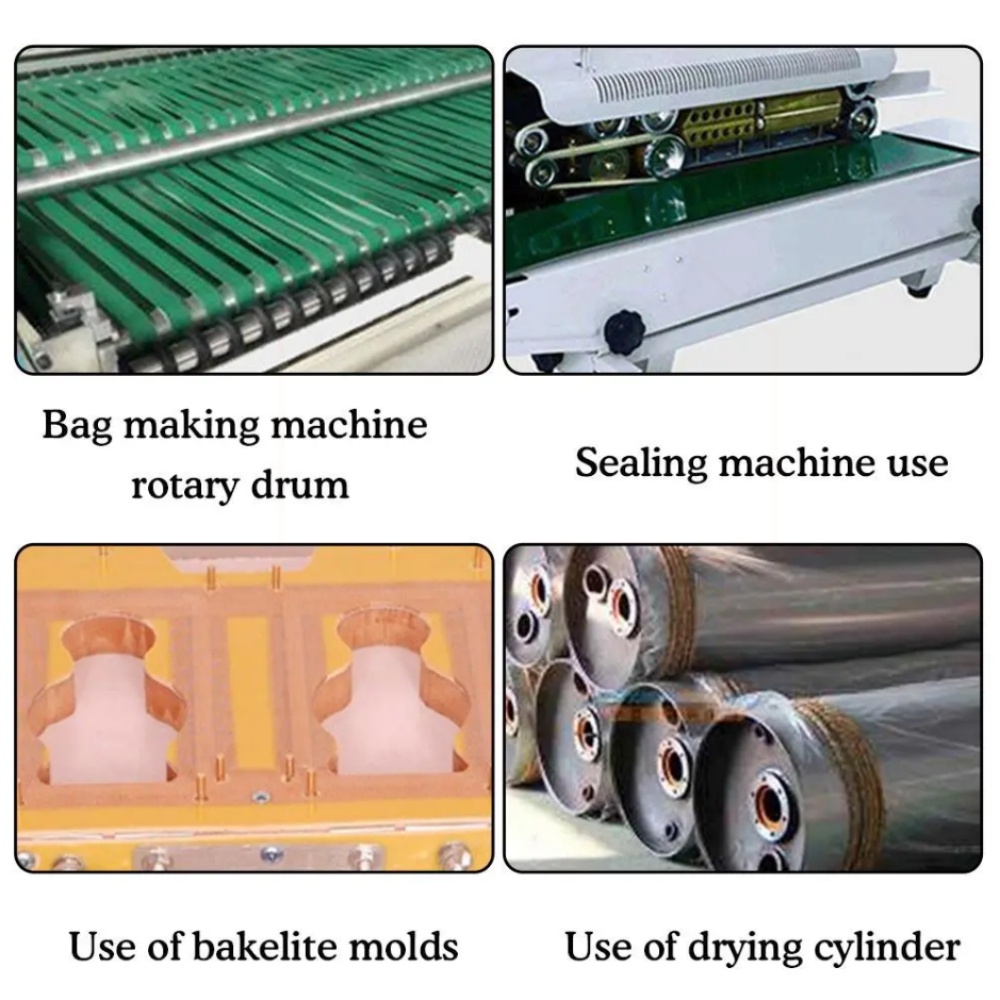

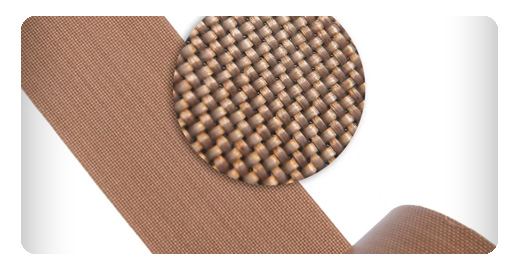

PTFE tape (polytetrafluoroethylene tape), also known as Teflon tape, is a special tape made of PTFE material. PTFE is a high molecular polymer with excellent performance. It is widely used in many industrial applications due to its excellent high temperature resistance, chemical corrosion resistance and low friction coefficient. PTFE tape is often used in occasions that require high temperature, chemical resistance and anti-sticking properties.

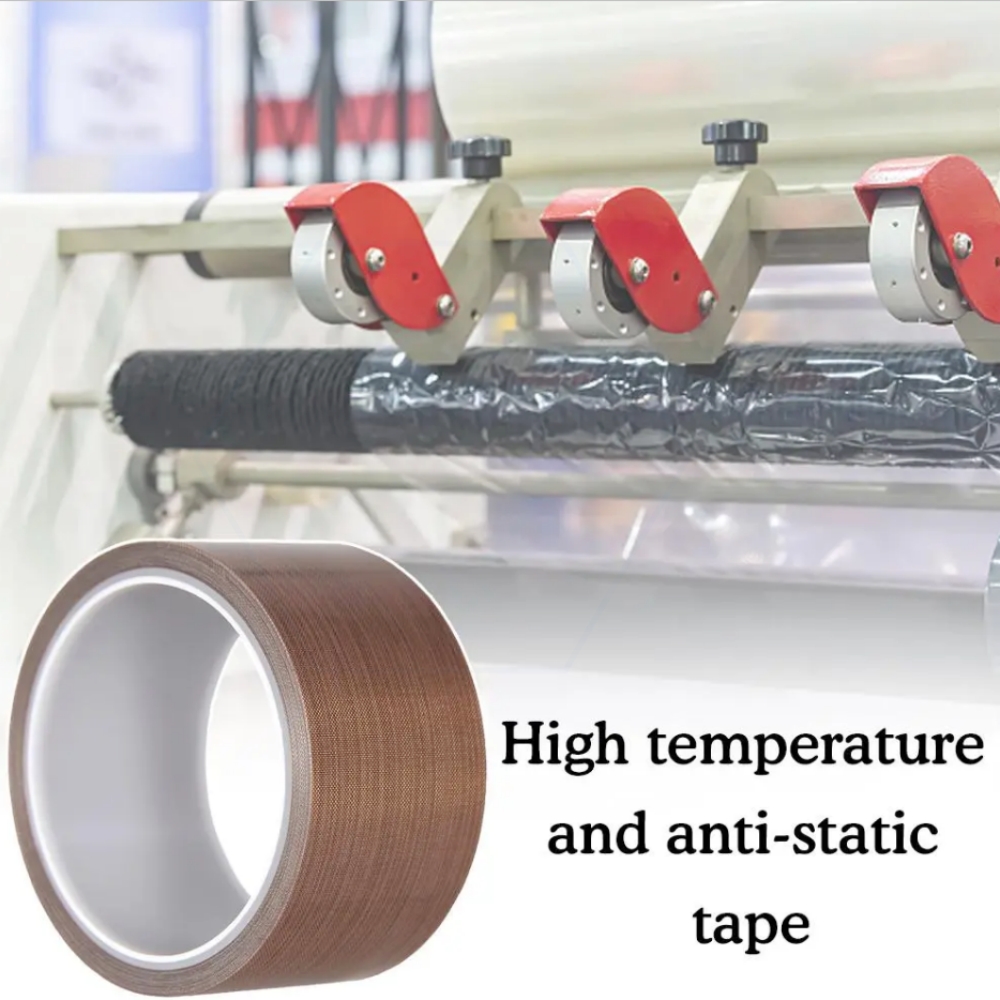

– Excellent high temperature resistance: PTFE tape can maintain its performance stable at extremely high temperatures, usually between -200°C and 260°C. This makes it very suitable for applications in high temperature environments, such as heat sealing, oven linings and electrical insulation.

– Excellent chemical corrosion resistance: PTFE materials are highly resistant to almost all chemicals and can resist corrosion by acids, alkalis, solvents and other chemicals. This property makes PTFE tape widely used in industries such as chemical, pharmaceutical and food processing.

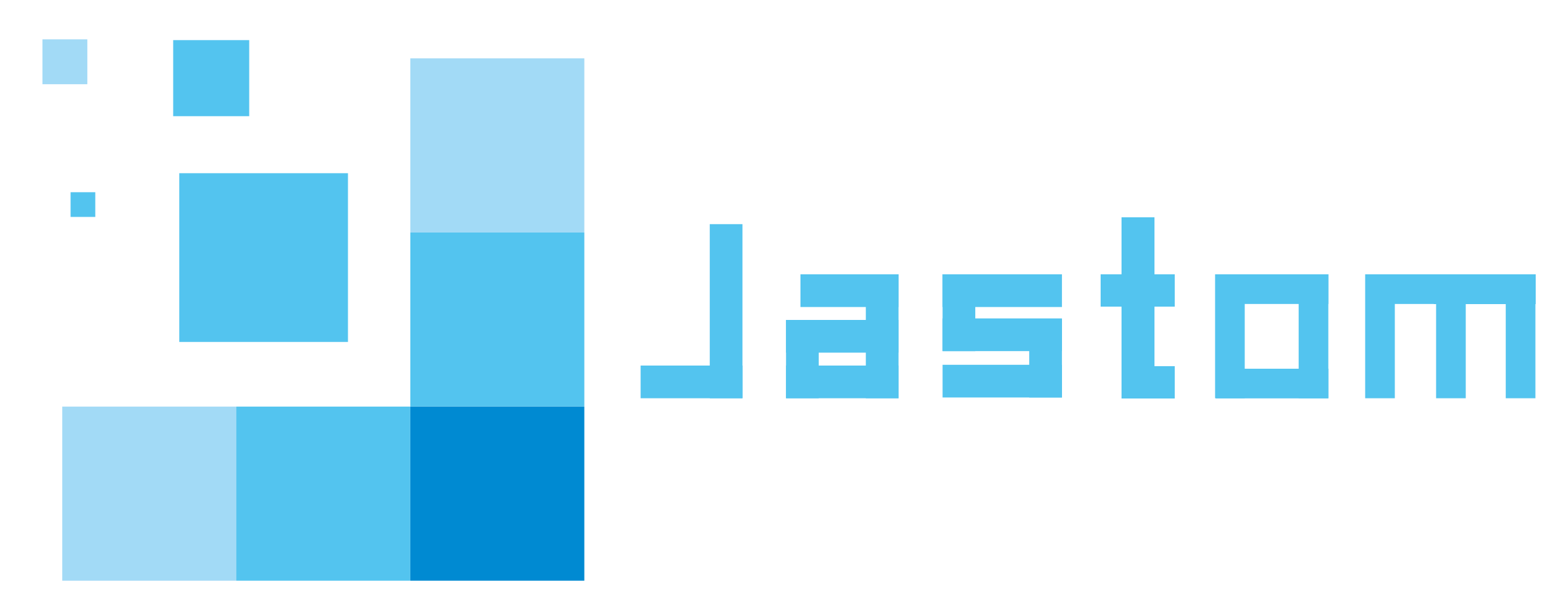

– Low friction coefficient and self-lubrication: PTFE tape has a smooth surface and an extremely low friction coefficient, which can provide good self-lubrication and prevent friction and adhesion between objects. This feature makes it important in mechanical equipment, conveyor belts and sliding devices.

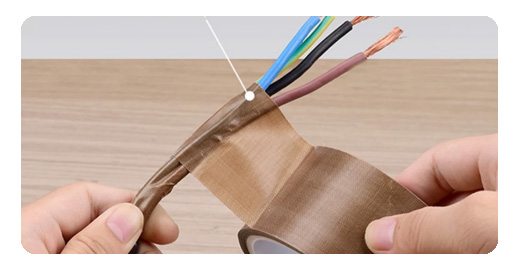

– Excellent electrical insulation performance: PTFE tape has excellent electrical insulation properties and can maintain stable insulation effects in high frequency and high voltage environments. This makes it an ideal insulating material in electronic, electrical and power equipment.

| ① Excellent electrical insulation performance The tape has excellent electrical insulation performance and can effectively prevent current leakage and short circuit. Its high dielectric strength ensures its application in various electrical equipment, protects wire joints and cable terminals, and ensures the safe operation of circuits. Whether in high or low voltage environments, PVC electrical tape can provide reliable insulation effect. |

| ② Good wear and weather resistance The wear resistance and weather resistance of PVC materials enable electrical tape to maintain its stable performance under harsh environmental conditions. It can resist the effects of wear, aging and ultraviolet rays, and is particularly suitable for use in outdoor and industrial environments. Whether it is exposed to sunlight for a long time or in a humid environment, PVC electrical tape can ensure long-term protection of electrical equipment. |  |

| ③ Flame retardancy The tape has excellent flame retardant properties, which can delay the spread of flames when a fire occurs and reduce the damage of fire to electrical equipment and lines. Its flame retardant performance meets a variety of international safety standards and is the key to the safe use of electrical equipment in high-risk environments. It can significantly reduce the risk of fire and ensure the safety of personnel and property. |

④ Good adhesion and flexibility The tape has strong adhesion and can firmly adhere to the surface of various wires and cables, ensuring stable installation and not easy to fall off. At the same time, its flexibility enables it to be easily wrapped around complex electrical structures without breaking or cracking. This feature makes the installation and maintenance of electrical tape more convenient and efficient, and it is suitable for various complex electrical environments. |  |

| Brand | JASTOM | Breathability | Airtight |

| Product Name | PTFE tape | Transparency | Usually opaque |

| Material | Polytetrafluoroethylene (PTFE) | Writability | Generally not writable |

| Color | Black、Brown (can be customized) | Environmental Protection | / |

| Size | 50M*50Mm*0.12Mm (Can Be Customized At Will) | Packing | Single roll packaging Or packaged according to customer requirements |

| Adhesive Type | Silicone, acrylic glue and other high temperature resistant adhesives | Use | Manual operation is sufficient, no special tools are required, and the construction is convenient |

| Viscosity | High viscosity to ensure a secure bond | Applicable Scene | High temperature environment, chemical industry, mechanical equipment, electronic and electrical, etc. |

| Temperature Resistance | -200°C to 300°C | Producing Country | China |

| Water Resistance | Excellent | Certificate Authentication | SGS |

| Tear Resistance | high | Label Customization | Logo Can Be Customized At Will |