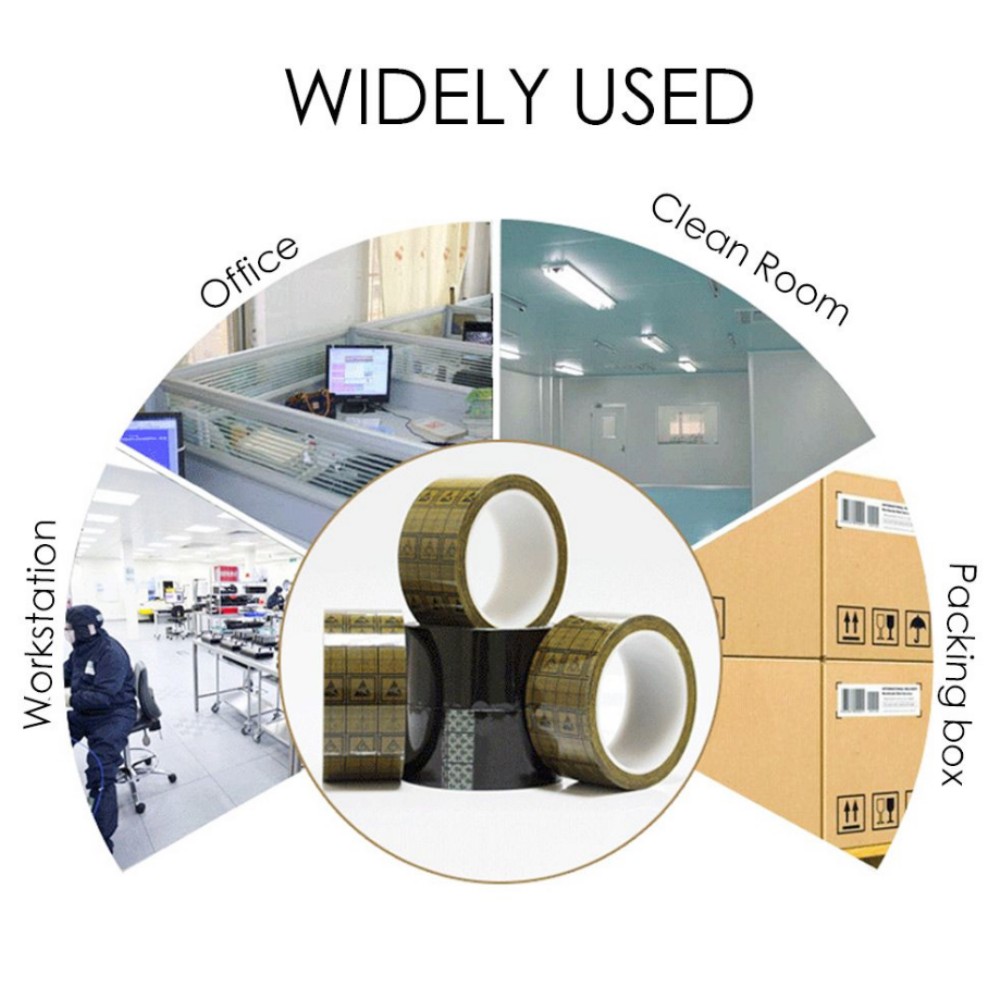

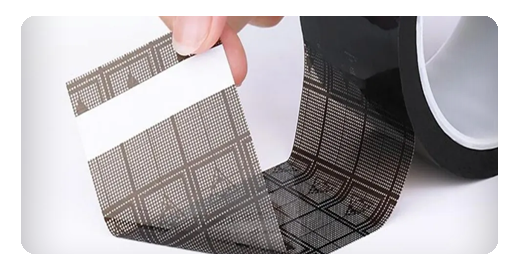

Antistatic tape is a tape specially designed to prevent the accumulation and release of static electricity. It consists of a base material and a conductive adhesive that can effectively control and dissipate static charge, thereby protecting sensitive electronic components and equipment from damage caused by electrostatic discharge (ESD). Antistatic tape is widely used in electronic manufacturing, semiconductors, optical equipment and other fields that are sensitive to static electricity.

– Antistatic performance: Antistatic tape has excellent antistatic properties and can effectively control the accumulation and release of static charges. It guides static charges to a safe area through conductive adhesives and substrates, thereby preventing damage to sensitive electronic components by electrostatic discharge (ESD). This makes antistatic tape an indispensable protective material in the electronic manufacturing and assembly process.

– Good adhesion: Antistatic tape has strong adhesion and can adhere firmly to various surfaces such as metal, plastic and glass. Its stable adhesion ensures that it will not fall off or shift during operation, providing long-lasting antistatic protection. This makes it effective in various industrial and manufacturing environments.

– High temperature and chemical resistance: Antistatic tape generally has high temperature resistance and can maintain its antistatic and adhesion properties in high temperature environments. In addition, it also has good chemical resistance and can resist the erosion of various chemicals, ensuring that it can still maintain stable performance in harsh working environments.

– Transparency and processability:Antistatic tape is usually transparent or translucent, which makes it easy to observe the protected electronic components and circuits. This transparency makes it more convenient during electronic assembly and maintenance. At the same time, antistatic tape is easy to cut and process, and can be customized according to actual needs to meet application requirements of different shapes and sizes.

| ① Excellent anti-static performance The tape can effectively control the accumulation and release of static electricity, and conduct static charge to the ground or |

| ② Strong adhesion The tape has strong adhesion and can be firmly attached to various surfaces such as metal, plastic, glass, etc., and will not fall off or shift easily. Its stable adhesion ensures that it maintains a good anti-static effect during use and is suitable for the packaging, fixation and protection of electronic products. |  |

| ③ High temperature and chemical resistance The tape has excellent high temperature resistance and can maintain its anti-static and adhesion properties in high temperature environments. This high temperature resistance makes it suitable for use in processes that require high temperature processing. In addition, the anti-static tape also has good chemical resistance and can resist the erosion of a variety of chemicals, making it suitable for various industrial environments. |

④ Transparency and processability Many anti-static tapes are transparent or translucent, which makes it easier for users to observe the protected electronic components and circuits during use. This transparency not only improves the convenience of operation, but also enables better inspection and maintenance of equipment. In addition, anti-static tapes are easy to cut and process, and can be customized according to actual needs to adapt to application requirements of different shapes and sizes. |  |

| Brand | JASTOM | Breathability | Airtight |

| Product Name | Antistatic tape | Transparency | Transparent and opaque optional |

| Material | Polyimide, PET, etc. | Writability | Markable and writable |

| Color | Black、Transparent (Can Be Customized) | Environmental Protection | / |

| Size | 50M*50Mm*0.12Mm (Can Be Customized At Will) | Packing | Single roll packaging Or packaged according to customer requirements |

| Adhesive Type | Conductive Adhesives | Use | Manual operation is convenient and fast |

| Viscosity | High viscosity to ensure a secure bond | Applicable Scene | Electronic manufacturing, semiconductors, optical equipment, etc. |

| Temperature Resistance | -40°C to 200°C | Producing Country | China |

| Water Resistance | Excellent | Certificate Authentication | SGS |

| Tear Resistance | High | Label Customization | Logo Can Be Customized At Will |